Imaging

3D Printing

Publications

News

Gallery

Contact

Team

3D Printing Research and Technology Development

High-Resolution and Multi-Material Additive Manufacturing

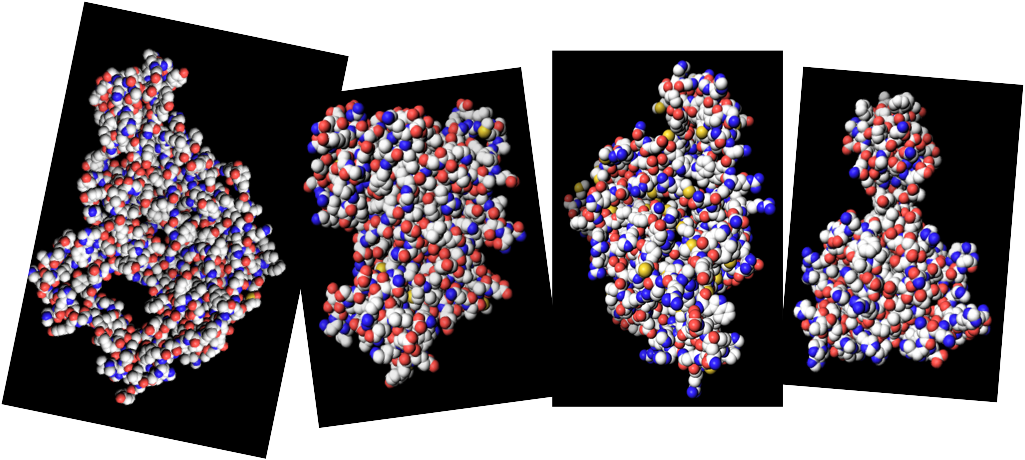

Our Additive Manufacturing team specializes in the development of new data processing, visualization, and fabrication tools for the high-throughput production of high-resolution tangible models for applications ranging from molecular and mathematical modeling, research instrumentation, pre-surgical planning and medical diagnostics, and architecture.

Our Tangible Proteomics team specializes in the development of additively manufactured multi-material molecular models for investigating protein-protein interactions in complex environments.

Stellar nurseries (molecular cloud simulations)

Model diameter: ca. 8 cm

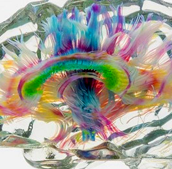

Transparent brain with integrated tractography data

Model diameter: ca. 8 cm

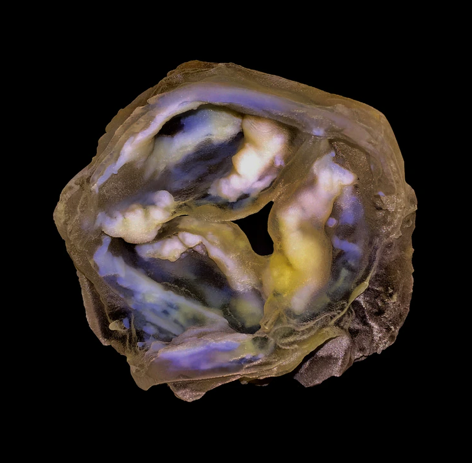

Variable modulus mineralized heart valve

Model diameter: ca. 10 cm

Photo-realistic sectioned human foot

Model diameter: ca. 15 cm

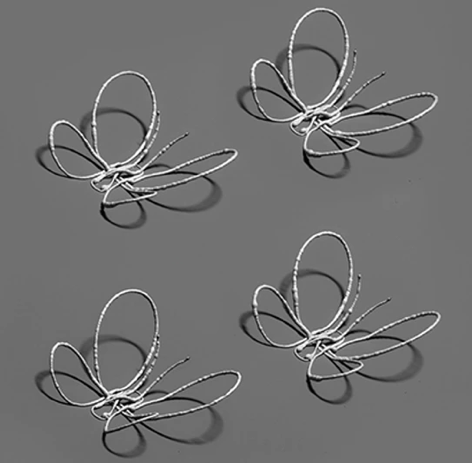

Laser-sintered metal butterflies

Model diameter: ca. 1 mm (each)

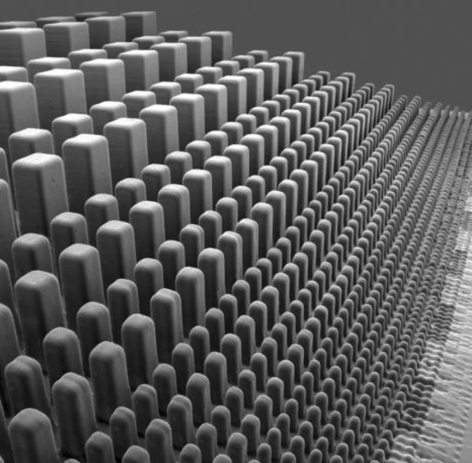

Dimensionally graded micro-pillar array

Model diameter: ca. 10 cm

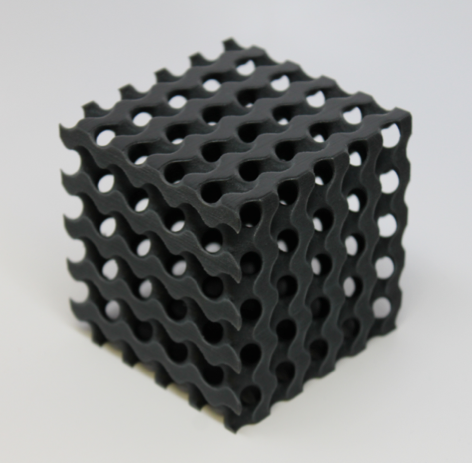

Flexible butterfly wing-inspired gyroid

Model diameter: ca. 8 cm

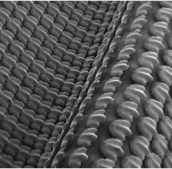

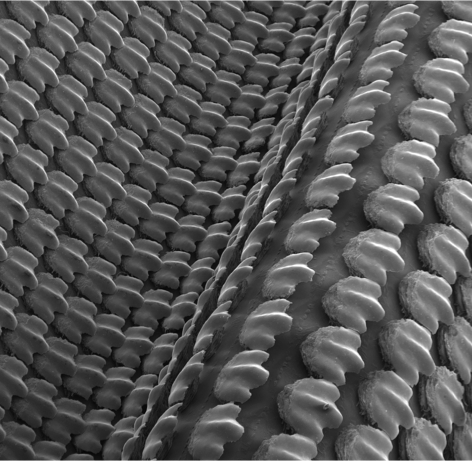

Flexible multi-material shark skin-inspired low-drag surface

Image diameter: ca. 5 cm

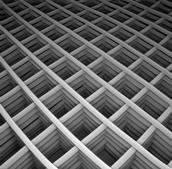

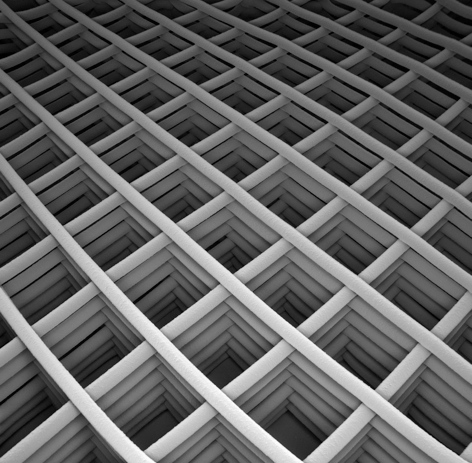

Ceramic micro-lattice

Model diameter: ca. 5 cm

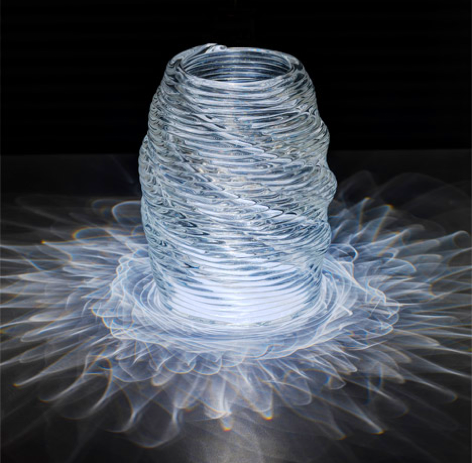

Macro-scale optically transparent glass

Model diameter: ca. 15 cm

Multi-material functionally graded jaw assembly

Model diameter: ca. 10 cm

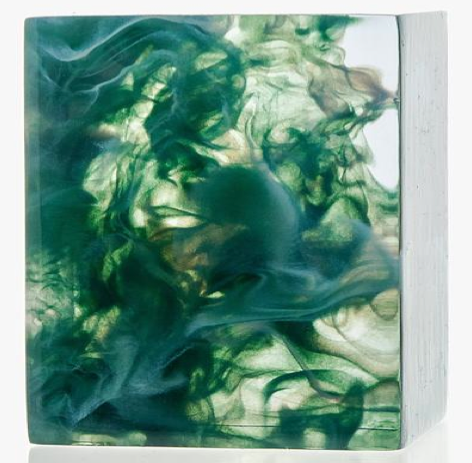

Fluid mixing simulation

Model diameter: ca. 10 cm

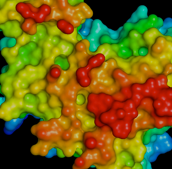

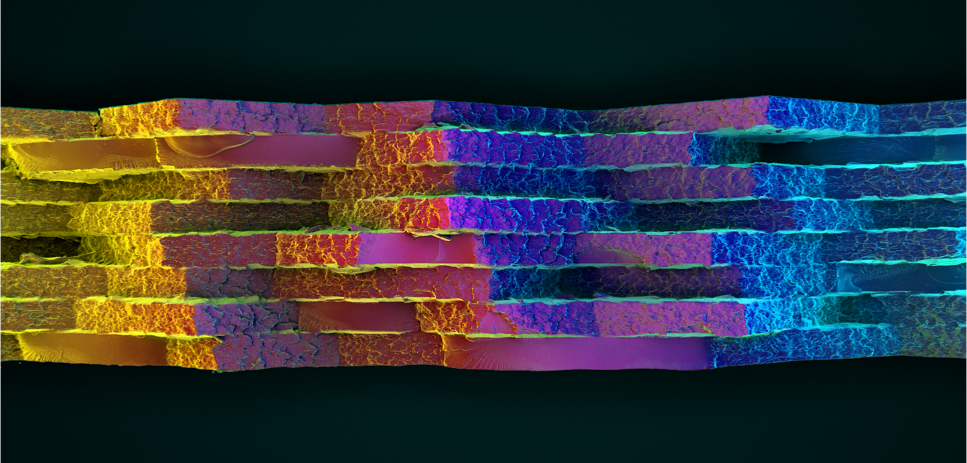

Multi-phase nacre-inspired composite (Polychromatic scanning electron micrograph of fracture surface)

Image width: ca. 5 cm

Research